Please fill out this form and send it to us to request for quote.

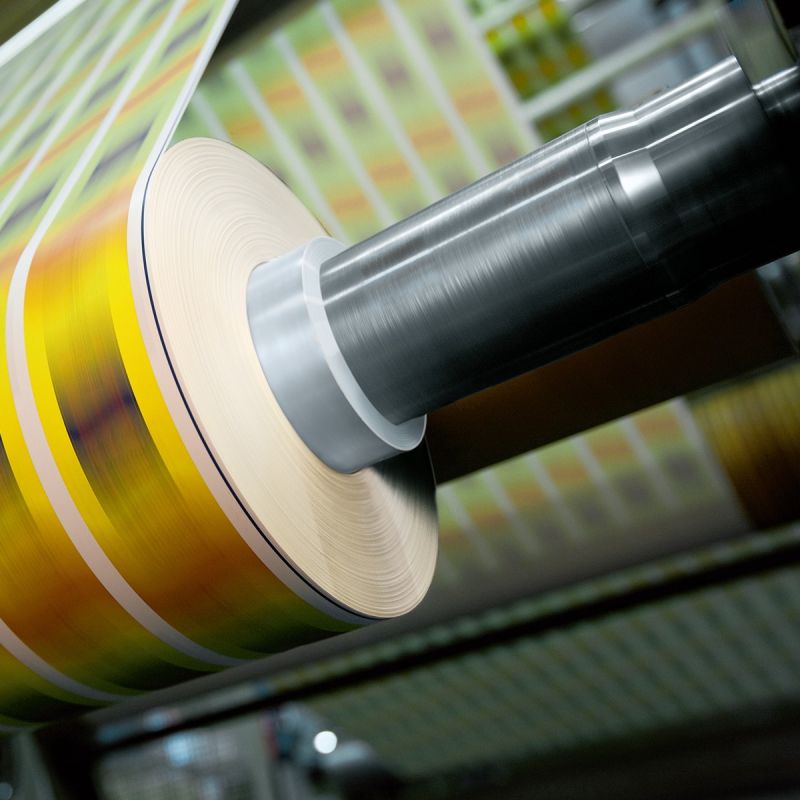

OPTIMISE WINDING PROCESSES, CUT COSTS AND PROTECT THE ENVIRONMENT

INOMETA offers the WinCore® winding core range for producing films and paper, internal further transport as well as for printing and finishing processes. All of our WinCore® winding cores are synonymous with maximum quality, even in the most challenging processes.

WinCore® winding cores epitomise our technical competence and our experience gained over the years with customers from the widest range of sectors.

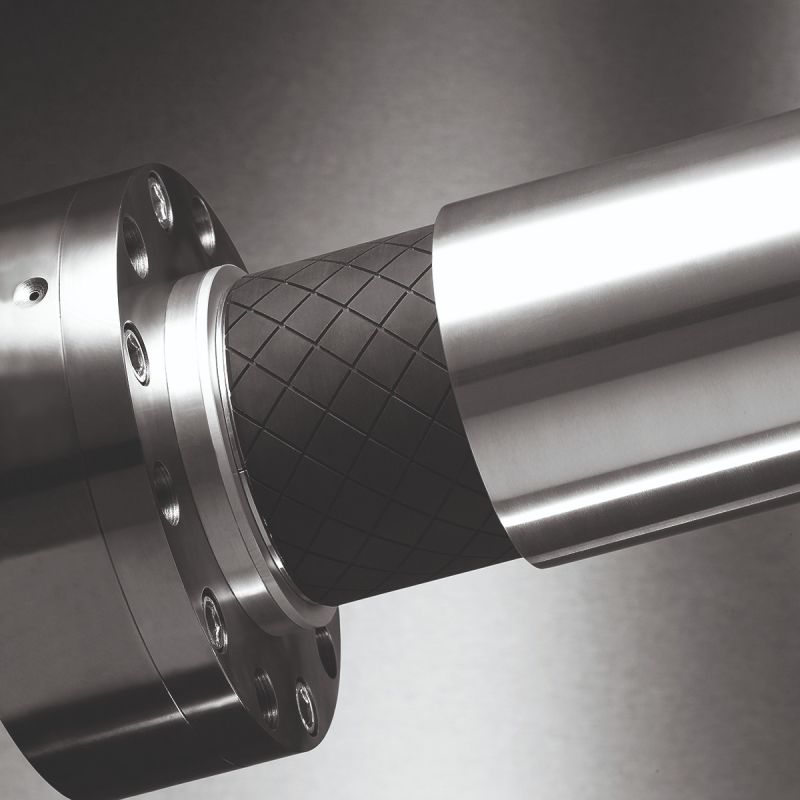

If your application is just as special – we will design the most suitable WinCore® winding core for you and adjust it in line with your requirements. In doing so, you will not only make technological progress, you will also reap the economic benefits of a considerably longer service life of the tube core, increased productivity and reduced downtimes.

Furthermore, you will gain economical sustainability, thanks to a considerably longer life cycle and versatile use.

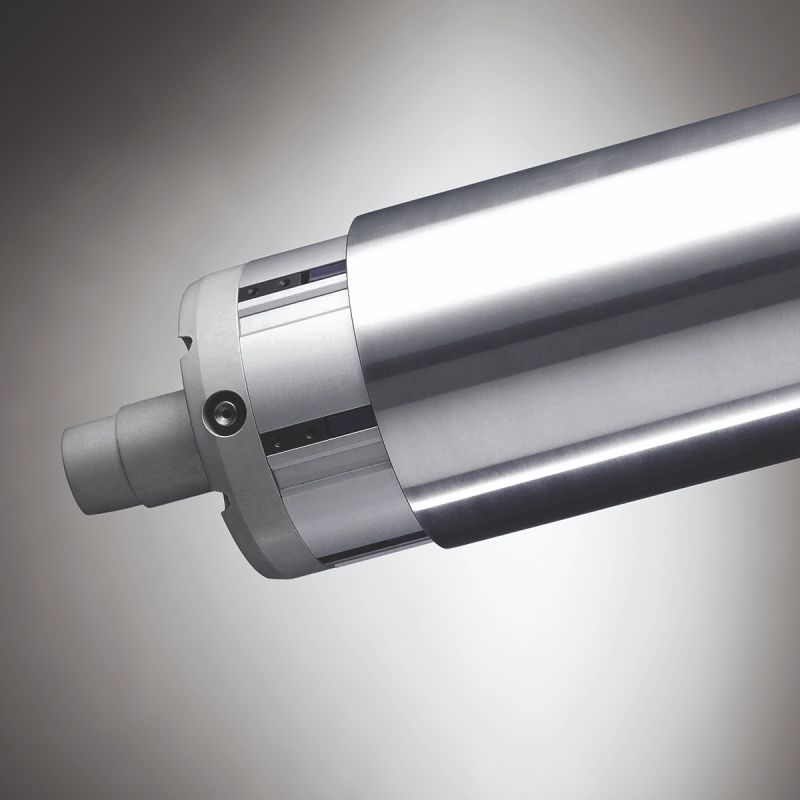

We provide WinCore® winding cores with inner diameter dimensions of 3″, 6″, 8″ and 10″.

The wall thickness is designed and calculated on an individual basis tailored to your requirements, meaning that you will always gain the optimum winding core for your application.

Our design criteria are based on the maximum roller diameter, roller weight, the maximum winding speed as well as the web width used.