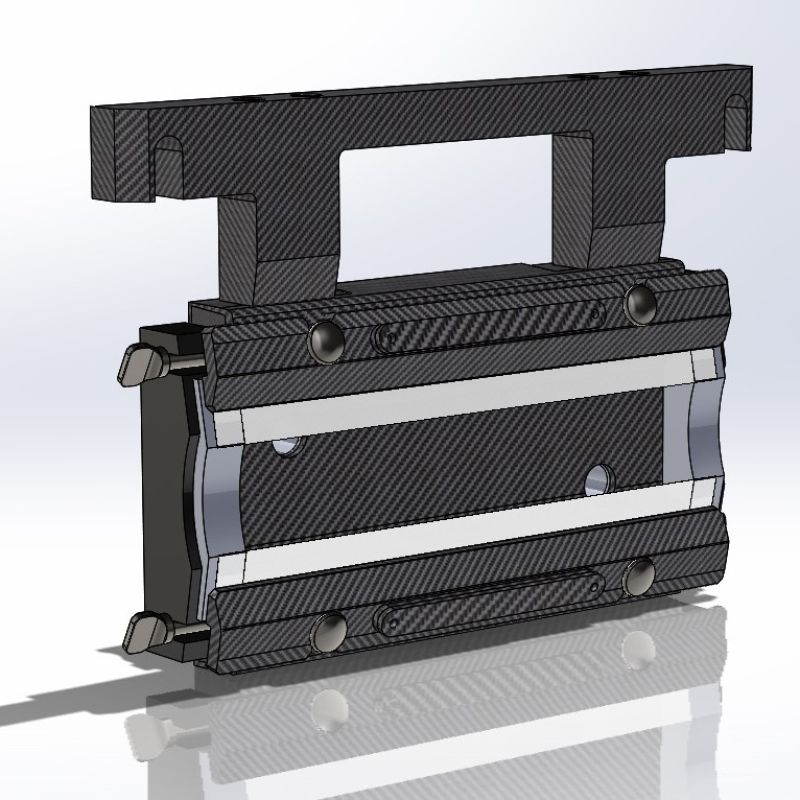

Ecoflex Carbon Fibre Doctor Blade sytems

Ecoflex is suitable for solvent, water based

or UV cured inks and coatings and may be retrofitted to any flexo

printer or gravure coater with web widths from 150 to 4000mm. It may

also be customised to meet the needs of specific applications, and a

wide range of anilox roll diameters can be accommodated with alternative

profiles available.

- Superior construction – carbon fibre has a stiffness and

rigidity 300% greater than aluminium which ensures consistent doctoring

and improved lay down - Corrosion free – carbon fibre does not suffer from any corrosion with water based or solvent inks and coating.

- Rapid changeover – complete tool-less blade and seal changeover

ensures downtime and make ready times are kept to an absolute minimum. - Ultra lightweight – carbon fibre is 70% lighter than aluminium

thus a 1200mm chamber weighs only 6.5kg – one operator can easily lift

chambers in and out of the press without lifting equipment - Auto Comp mounting system – A simple two position mounting

system automatically compensates for blade wear and ensures precision

blade to anilox roll positioning on every set up - Minimum volume – The small volume of the enclosed chamber

compared to open tray systems ensures a significant reduction in ink and

coating use.

With stiffness and rigidity 300% greater than aluminium, the superior construction of carbon fibre ensures consistent doctoring and improved lay down. The unique Delpro blade sandwiches unidirectional fibres within outer cross-weave layers to provide an optimum combination; the cross weave fibres being more aesthetic and bringing integrity to the outer layers with the unidirectional fibres providing essential, consistent rigidity across the length of the cylinder where it is needed most.

SPECIFICATION

- Web width range : 150 to 4000mm

- Continuous web or sheet fed machinery

- Solvent, water based or UV cured inks, coatings and varnishes

- Retro fit to any flexo printer, gravure coater or offset lacquering station

- Custom designs available for specific applications

FEATURES

- Ultra lightweight, one operator easily lifting chambers in and out of the press without lifting equipment.

- Complete tool-less blade and seal changeover ensures minimal downtime keeping makeready times to an absolute minimum.

- Carbon fibre is free from any corrosion with water based or solvent inks and coating.

- Simple two-position auto comp mounting system automatically compensates for blade wear and ensures precision blade to anilox roll positioning on every set up. Micrometer adjust system also available.

- Small volume of enclosed chamber compared with open tray ensures significant reduction in ink and coating use.

- The chamber is manufactured from carbon fibre with a stiffness and rigidity 300% greater than aluminium. This superior rigidity provides consistent doctoring and improved profile of lay-down

- chambers use a unique combination of both unidirectional and cross-weave fibres. Sandwiching unidirectional fibres within outer cross-weave layers provides the optimum combination. The cross weave fibres are more aesthetic and provide more integrity to the outer layers but the unidirectional fibres continue to provide the essential and consistent rigidity across the length of the cylinder where it is needed most.

- Carbon Fibre is 70% lighter than aluminium and thus the total weight of each chamber including all fittings would be approximately 15kg which complies with current Manual Handling regulations.

- Carbon Fibre does not suffer from any corrosion with water based or solvent inks and each chamber has a 15 year anti-corrosion guarantee.

- The chambers have a smooth surface which, together with the corrosion free properties ensures it remains easy to clean.

- The chambers have a quick release design of all components which ensures blade and seal replacement times are kept to a minimum – typically 2-3 minutes per deck.

- The chamber is fixed to the mounting system with a tool-less clamping handle enabling each chamber to be removed or re-fitted in 30 seconds or less.

- The Auto-Comp mounting system is a simple 2 position system which automatically compensates for blade wear without the need for operator adjustment and guarantees that the chamber returns to the correct repeatable position.

- The CFDB system is completely enclosed, minimising aeration and solvent evaporation, reducing contamination and maintaining viscosity and quality of inks.