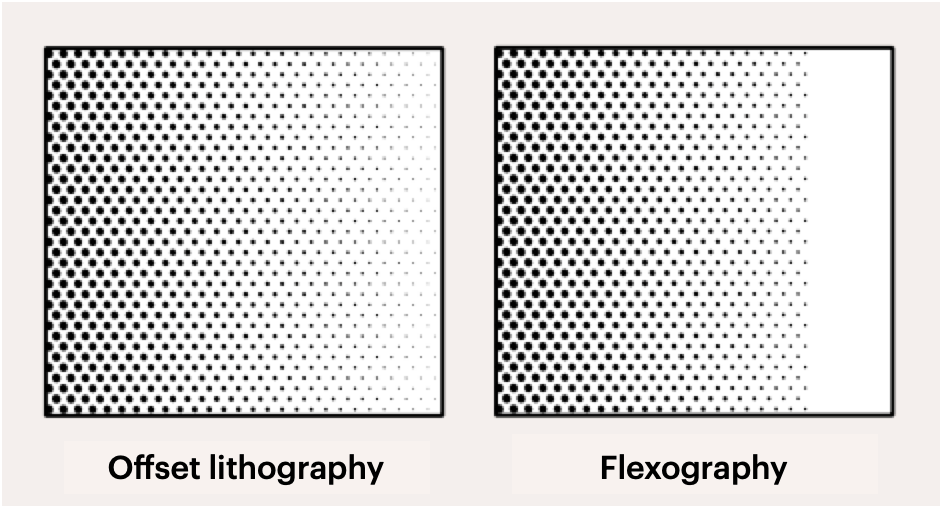

The process of flexo printing is very different from that of offset printing. There are many similar issues to screen printing, but they are much more serious. The printing plates are made of very flexible polymers, with different colurs used by different manufacturers. Translucent in some ways. It is common for these printing plates to have very raised images and halftone dots that are quite noticeable.

It should be obvious that printing is a highly technical process.

A special consideration and thoughtful approach are necessary when designing for flexo.

To conceptualise a winning package that won’t disappoint when it comes off the press onto the shelf, package designers must understand the differences between flexo, offset, or gravure media just like an artist must know the difference between watercolours and oils.

In order to accomplish the goal, the designer must be familiar with flexo printing graphic. Overprinting, trapping, colour separation, distortion factor and colour separation are all technical aspects of the job.

Here is a checklist for designers to use to ensure that their designs are suitable for flexo printing:

- Provide design files in .ai, .indd, or .ap format at 1:1 scale

- Include a colour printout or PDF file

- In both converted and unconverted versions, texts should be included:

- All fonts included (unconverted)

- It has been converted (text has been turned into graphics)

- The size, color, and shape of all elements should be customizable. Ensure that all external elements are included.

- Generally, we need to be able to open PDF files in Illustrator or ArtPro.

- Please note in colour separation:

- Images should be modified using Photoshop

- Colour separation must be CMYK not RGB

- Separations should have high contrast in respect of both grey level and hue

- A minimum of 300 PPI should be used

- Location and size of photocell mark should be specified.

- Printed and non-printed areas and folding lines should be marked clearly.

- Please note:

- Transparent film requires a white base colour under the printed areas.

- White pigmented film will provide a better base for half-tone images than white colour on transparent film.

- A white base is essential for lamination work, and should be taken into account when specifying the total colour count.